Single Pendulum vs. Double Pendulum Welding

Sep 05, 2025Single pendulum and double pendulum welding are widely used techniques in laser welding. Both are advanced forms of oscillation welding and are suitable for a variety of applications. They operate based on different principles. In single pendulum welding, the laser beam oscillates in one direction, while in double pendulum welding, the beam oscillates simultaneously in both horizontal and vertical directions.

The pendulum system is crucial in laser welding. It refers to the mechanism that controls the movement of the laser beam, creating a specific oscillation path. This helps distribute heat more evenly across the joint, improves weld quality, and reduces defects. Single pendulum systems move along one axis, while double pendulum systems enable two-axis oscillation, providing greater efficiency and precision.

Single pendulum welding involves a welding head that oscillates back and forth during the process, similar to a simple pendulum. This motion distributes heat evenly and strengthens the joint. It is commonly used for small tasks and can weld in confined spaces. The technology is particularly suitable for thin materials, offering stable welds and fewer defects.

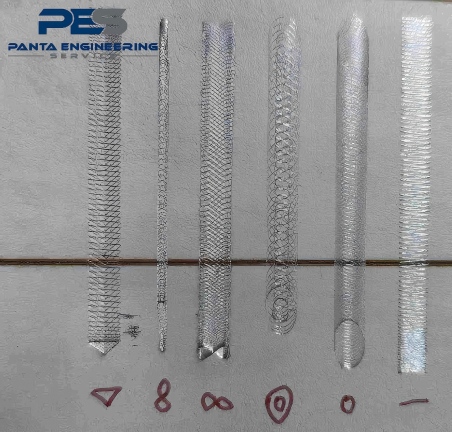

Double pendulum welding operates with beam oscillation in both directions. The laser beam moves left and right while also moving up and down, similar to two pendulums working together. This enables the beam to create a variety of oscillation patterns, such as triangles, circles, or figure eights. These shapes improve flexibility, heat dissipation, and overall weld quality, making the process highly effective for complex designs and thicker materials.

Structurally, single pendulum welding is best suited for light-duty work, narrow joints, and thin flat surfaces. It produces smooth welds with good stability but is limited in handling thicker sections. Double pendulum welding, on the other hand, provides greater control and adaptability. It handles curves, thicker joints, and complex geometries with higher precision and deeper penetration.

Maintenance requirements also differ. Single pendulum systems are simpler to operate, with fewer moving parts and lower maintenance needs. Double pendulum systems are more complex and require additional setup and adjustment, but once mastered, they offer significant long-term benefits.

In terms of efficiency, single pendulum welding is widely used for straightforward applications in automotive, construction, and general manufacturing. Double pendulum welding is preferred where higher efficiency and more demanding tasks are required, including aerospace and advanced automotive applications.

Cost is another factor. Single pendulum machines are more affordable due to their simpler design and lower maintenance requirements, making them popular for basic projects and smaller budgets. Double pendulum machines are more expensive because of their advanced system and higher maintenance needs, but they provide long-term value for high-volume and precision applications.

When choosing between the two, the decision depends on project requirements. For thin materials and simple welds, single pendulum welding is sufficient. For higher precision, complex designs, or thicker sections, double pendulum welding is the better choice. While more costly, it offers superior control, weld strength, and overall reliability.

Double pendulum welding also supports multiple oscillation modes to meet different requirements. Linear mode provides straight joints, circular mode enhances heat distribution, and figure-eight mode is effective for deeper welds. Triangle and double triangle modes improve fusion, while double arc mode strengthens weaker joints. This versatility makes double pendulum welding highly adaptable to a wide range of applications.

Como podemos te ajudar?